| |

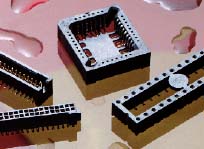

Insulator

bodies should be designed to expose the lead/solder pad interface, when

possible, for easy cleaning and inspection of the solder joints and to

reduce the effects of IR shadowing. (In IR systems not employing convection,

components that are shadowed, or not directly exposed to the IR heat source,

are heated more slowly than those receiving direct exposure, thus requiring

longer soldering times or temperatures.) Socket and terminal strips are

usually gull-winged with the leads out and exposed. Hidden leads, a concern

with DIP and PLCC sockets where the leads are normally turned in to minimize

board space, are exposed with open body designs. Insulator

bodies should be designed to expose the lead/solder pad interface, when

possible, for easy cleaning and inspection of the solder joints and to

reduce the effects of IR shadowing. (In IR systems not employing convection,

components that are shadowed, or not directly exposed to the IR heat source,

are heated more slowly than those receiving direct exposure, thus requiring

longer soldering times or temperatures.) Socket and terminal strips are

usually gull-winged with the leads out and exposed. Hidden leads, a concern

with DIP and PLCC sockets where the leads are normally turned in to minimize

board space, are exposed with open body designs.

|